Transformer Oil on-Line Monitoring System

Basic Info

Model No.: VGTCA-3600

Product Description

Model NO.: VGTCA-3600 Protection: Corrosion Resistance Housing: Steel HS Code: 84 Certification: ISO9001 Installation: Vertical Origin: Ningbo China Exact understanding of the running status of the transformer is the key to maintain the safe operation of the

power system.

If local overheating or partial discharge is present in the transformer, the insulating oil or solid insulator in the

trouble location will release small molecules hydrocarbon gases such as CH4, C2H6, C2H4, C2H2 and other

gases such as H2, CO, CO2. Both of the concentration of every gas in insulating oil and the total concentration

of inflammable gas in oil (TCG) can be used as indicators to diagnose the internal faults of the transformer.

Transformer Oil On-line Monitoring System is a new transformer oil chromatogram on-line monitoring

product. Our company researches and develops the product by taking International Electrotechnical

Commission (IEC) Standard and National Standard of Transformer Oil Monitoring of China Electric Power

Industry (GB) as test research and development basis strictly, introducing advanced detection technology and

high-precision detection components from abroad and absorbing the field operating experience of on-line

chromatogram monitoring system for gas in transformer oil at home and abroad.

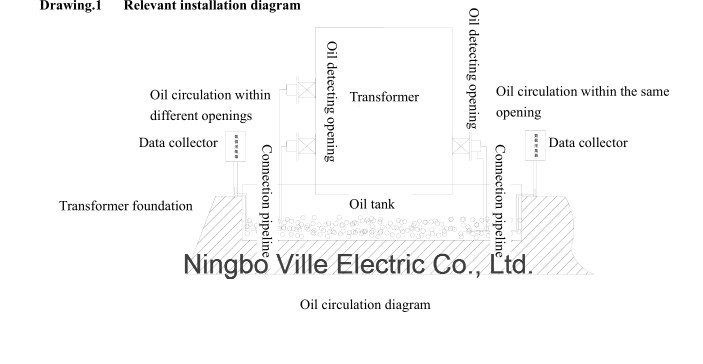

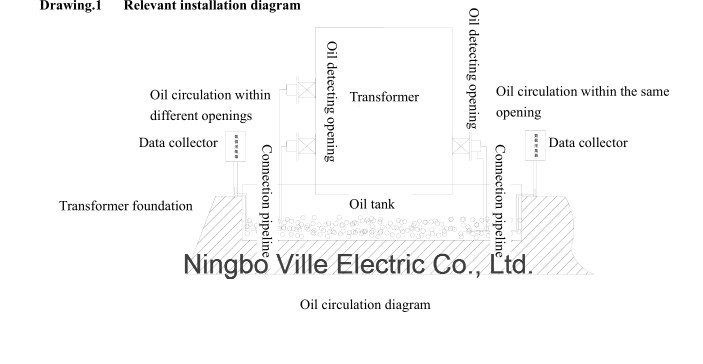

Transformer Oil On-line Monitoring System adopts oil gas degassing technology that combines vacuum and

ultrasound, uses the international newest high efficiency compound chromatographic column and

high-precision sensor to accurately analyze seven gases with fault features including hydrogen (H2), carbon

monoxide (CO), methane (CH4), ethane C2H6), ethylene (C2H4), acetylene (C2H2) and carbon dioxide (CO2)

and to assist in realizing on-line analysis of micro-water in oil.

Transformer fault information can be captured promptly by using Transformer Oil On-line Monitoring System

to scientifically guide the operation and maintenance of the equipment.

Technical indexes of system:

Item Content

Detection principle :Detect H 2 , CO, CH 4 , C 2 H 6 , C 2 H 2 , C 2 H 4 or CO 2 , O 2 , where micro-water can be

detected.

Degassing method : Vacuum and ultrasound degassing

Separating method :Special single chromatographic column

Detection method : Special single gas sensor

Sampling methods : Digital automatic quantification sampling

Temperature control : Dual-loop thermostatic control

Data collection Adjustable circuit design, automatic peak capturing and appearance section gain

communication mode RS485,TCP/IP,GPRS

Network protocol

Support TCP/IP network protocol, support remote monitoring and remote

maintenance

Display mode

Report/trend chart/incremental analysis, data can be incorporated in user

monitoring network

Display content H 2 ,CO,CO 2 ,CH 4 ,C 2 H 6 ,C 2 H 2 ,C 2 H 4 ,O 2 ,TCG

Alarm mode

Any set concentration, incremental alarm value; audible and visual alarm; spot

remote transmission of alarm signal

analytical cycle System default 24 hours/times, 2 hours to the minimum, set by user

Data storage 20 years

Temperature control

precision

±0.1ºC

Environment

temperature

-40ºC~+85ºC

Relative humidity 5-95% No condensation

Maximum daily

temperature difference

30ºC

Sunlight intensity 1kW/m2 (wind speed 0.5m/s)

Pollution level External insulation creepage distance 25mm/kv

Ice cover thickness 20mm (when wind speed is not more than 15m/s)

Working Power Supply Alternating current 220V±10%,50Hz

Carrier gas 99.999% of nitrogen gas, pressure 0.12-0.25Mpa

Installation size 800(length)×550(width)×1400(height)mm

Anti-vibration 5-17Hz,0.1" bimodal shift; 17-640Hz, 1.5G peak-to-peak acceleration

Anti-impact Acceleration: 10G peak-to-peak

Contact us if you need more details on Oil on Line Monitoring System. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Transformer Oil on Line Monitoring、Transformer Oil Monitoring. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Oil on Line Monitoring System. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Transformer Oil on Line Monitoring、Transformer Oil Monitoring. If these products fail to match your need, please contact us and we would like to provide relevant information.

power system.

If local overheating or partial discharge is present in the transformer, the insulating oil or solid insulator in the

trouble location will release small molecules hydrocarbon gases such as CH4, C2H6, C2H4, C2H2 and other

gases such as H2, CO, CO2. Both of the concentration of every gas in insulating oil and the total concentration

of inflammable gas in oil (TCG) can be used as indicators to diagnose the internal faults of the transformer.

Transformer Oil On-line Monitoring System is a new transformer oil chromatogram on-line monitoring

product. Our company researches and develops the product by taking International Electrotechnical

Commission (IEC) Standard and National Standard of Transformer Oil Monitoring of China Electric Power

Industry (GB) as test research and development basis strictly, introducing advanced detection technology and

high-precision detection components from abroad and absorbing the field operating experience of on-line

chromatogram monitoring system for gas in transformer oil at home and abroad.

Transformer Oil On-line Monitoring System adopts oil gas degassing technology that combines vacuum and

ultrasound, uses the international newest high efficiency compound chromatographic column and

high-precision sensor to accurately analyze seven gases with fault features including hydrogen (H2), carbon

monoxide (CO), methane (CH4), ethane C2H6), ethylene (C2H4), acetylene (C2H2) and carbon dioxide (CO2)

and to assist in realizing on-line analysis of micro-water in oil.

Transformer fault information can be captured promptly by using Transformer Oil On-line Monitoring System

to scientifically guide the operation and maintenance of the equipment.

Technical indexes of system:

Item Content

Detection principle :Detect H 2 , CO, CH 4 , C 2 H 6 , C 2 H 2 , C 2 H 4 or CO 2 , O 2 , where micro-water can be

detected.

Degassing method : Vacuum and ultrasound degassing

Separating method :Special single chromatographic column

Detection method : Special single gas sensor

Sampling methods : Digital automatic quantification sampling

Temperature control : Dual-loop thermostatic control

Data collection Adjustable circuit design, automatic peak capturing and appearance section gain

communication mode RS485,TCP/IP,GPRS

Network protocol

Support TCP/IP network protocol, support remote monitoring and remote

maintenance

Display mode

Report/trend chart/incremental analysis, data can be incorporated in user

monitoring network

Display content H 2 ,CO,CO 2 ,CH 4 ,C 2 H 6 ,C 2 H 2 ,C 2 H 4 ,O 2 ,TCG

Alarm mode

Any set concentration, incremental alarm value; audible and visual alarm; spot

remote transmission of alarm signal

analytical cycle System default 24 hours/times, 2 hours to the minimum, set by user

Data storage 20 years

Temperature control

precision

±0.1ºC

Environment

temperature

-40ºC~+85ºC

Relative humidity 5-95% No condensation

Maximum daily

temperature difference

30ºC

Sunlight intensity 1kW/m2 (wind speed 0.5m/s)

Pollution level External insulation creepage distance 25mm/kv

Ice cover thickness 20mm (when wind speed is not more than 15m/s)

Working Power Supply Alternating current 220V±10%,50Hz

Carrier gas 99.999% of nitrogen gas, pressure 0.12-0.25Mpa

Installation size 800(length)×550(width)×1400(height)mm

Anti-vibration 5-17Hz,0.1" bimodal shift; 17-640Hz, 1.5G peak-to-peak acceleration

Anti-impact Acceleration: 10G peak-to-peak

Contact us if you need more details on Oil on Line Monitoring System. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Transformer Oil on Line Monitoring、Transformer Oil Monitoring. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Oil on Line Monitoring System. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Transformer Oil on Line Monitoring、Transformer Oil Monitoring. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Transformer Spare Parts > Others Transformer Spare Parts

Premium Related Products

Other Products

Hot Products

Centrifugal Ventilation Fan with Good QualityGood Price for Vacuum Circuit Breaker of High Quality and Low VoltagePower SaverRectifier Transformer /Oil Immersed Power TransformerPassive Power Filter (Low Voltage)DC Power Distribution Board of Transformer SubstationThree Phase Resin Insulation Dry Type Power TransformerDistribution Transformer /Power Transformer/Power SubstationCable Distribution Box for Outdoor High VoltageAuto Transformer 330kv-500kv Power Transformer Furnace Transformer220kv Combination Power TransformerElectric Arc Furnace Transformer /Power Supply Transformer Power Distribution TransmissionPackaged Box Type Power Transmission SubstationHigh Voltage Vacuum Circuit Breaker for IndoorMetal Clad Switchgear of Medium / High VoltageMetal Clad Switchgear of High Voltage