on-Load Tap Changer for Transformer Load Break Switch Tap Changer

Basic Info

Model No.: SV

Product Description

Model NO.: SV Connection Method: Y,D No of Contact: The Thin Contacts Are 10 or 14 No of The Middle Position: in The Middle Part There Are 0,1,3, Trademark: VILLE Origin: Ningbo Max Rated Current: 200A 350A Rated Voltage: 35kv or 66kv No Ofworking Position: It Could Reach 19 or 27 Positions. Voltage Regulating Method: Positive and Negative Voltage Specification: IEC CE, ISO HS Code: 85 The structure of SV on-load tap-changer

Compared with other products, we made some improvements as follows:

1. Change the selector

At present, the domestic products still use the old foreign structure, i. E., the movable contact makes connection with the fixed contact. This structure has a large torque. Our company switched over to the traditional docking structure with good contacts and small torque. The insulation bracket is made from three isolated wall with a high-to-ground withstand voltage.

2. Under flange improvement

The under-flange s made of engineering plastics and lifted by four screws. While in the accidents, the increased pressure often damage the under-flange (it occurs at home and abroad ). Therefore, our company strengthens the prone-to-crack place to ensue good strength.

3. Correct arc principle

Some domestic manufacturers apply with slide between are contact and rotating pole. When the arc contact leaves from the fixed contact, the current will breaks, and the current passes through arc contact to the rotating rod. As the gap between the two can only connect by the arc, the rotating rod will burn off and the gap will get larger, resulting in the broken of the rotating poles, thus accidents arise. We considered of this and take appropriate measures.

4. Correct resistance installation

Products of the same kind at home and abroad have no outer resistance baffle. Resistance will be scattered in accidents. Under the effect f elasticity, it collapses which cause the tapping short circuit and threaten the safety of the transformer. We add one baffle at the outer layer of resistances as a preventive measure, enhancing the reliability.

Type designation

Voltage-regulating method: W— Positive— Negative voltage— Regulating G— — Thickness regulating

No. Of the middle position: In the middle part there are 0, 1 and 3.

No. Of working position: It could reach 19 or 27 positions.

No. Of contact: The thin contacts are 10 or 14.

Voltage grade (kV): Rated insulation level: 35 kV or 66 kV.

Connection method: Y— Neutral connection, D— Other connection

Max. Rated current (A): 200A, 350A

No. Of phase: III — Three-phase I— Single-phase

E. G. SV III 350 Y — 66 — 10 193 W

SV series switch, three-phase, maximum rated current 350 A, neutral connect, voltage at 66 kV, 10 contacts for thin-regulating, 19 working positions, 3 middle-position, which conversion selector, positive-negative regulating.

Contact us if you need more details on Transformer Tap Changer. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tap Changer for Transformer、On Load Tap Changer. If these products fail to match your need, please contact us and we would like to provide relevant information.

Compared with other products, we made some improvements as follows:

1. Change the selector

At present, the domestic products still use the old foreign structure, i. E., the movable contact makes connection with the fixed contact. This structure has a large torque. Our company switched over to the traditional docking structure with good contacts and small torque. The insulation bracket is made from three isolated wall with a high-to-ground withstand voltage.

2. Under flange improvement

The under-flange s made of engineering plastics and lifted by four screws. While in the accidents, the increased pressure often damage the under-flange (it occurs at home and abroad ). Therefore, our company strengthens the prone-to-crack place to ensue good strength.

3. Correct arc principle

Some domestic manufacturers apply with slide between are contact and rotating pole. When the arc contact leaves from the fixed contact, the current will breaks, and the current passes through arc contact to the rotating rod. As the gap between the two can only connect by the arc, the rotating rod will burn off and the gap will get larger, resulting in the broken of the rotating poles, thus accidents arise. We considered of this and take appropriate measures.

4. Correct resistance installation

Products of the same kind at home and abroad have no outer resistance baffle. Resistance will be scattered in accidents. Under the effect f elasticity, it collapses which cause the tapping short circuit and threaten the safety of the transformer. We add one baffle at the outer layer of resistances as a preventive measure, enhancing the reliability.

Type designation

Voltage-regulating method: W— Positive— Negative voltage— Regulating G— — Thickness regulating

No. Of the middle position: In the middle part there are 0, 1 and 3.

No. Of working position: It could reach 19 or 27 positions.

No. Of contact: The thin contacts are 10 or 14.

Voltage grade (kV): Rated insulation level: 35 kV or 66 kV.

Connection method: Y— Neutral connection, D— Other connection

Max. Rated current (A): 200A, 350A

No. Of phase: III — Three-phase I— Single-phase

E. G. SV III 350 Y — 66 — 10 193 W

SV series switch, three-phase, maximum rated current 350 A, neutral connect, voltage at 66 kV, 10 contacts for thin-regulating, 19 working positions, 3 middle-position, which conversion selector, positive-negative regulating.

| Type | SV350 | SV200 | |||||

| Max.rated current (A) | 350 | 200 | |||||

| No. Of phases | 1 | 3 | 3 | 1 | 3 | 3 | |

| Connect Method | _ | Y | D | _ | Y | D | |

| Short-current test current (kA) | Heat stabilization (3 seconds. ) Act-stabilization (peak value ) | 5 12.5 | 4 10 | ||||

| Voltage between grades (V) | Spot 10 Spot 12 Spot 14 | 1500 1400 1000 | 1500 1400 1000 | ||||

Contact us if you need more details on Transformer Tap Changer. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tap Changer for Transformer、On Load Tap Changer. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Transformer Spare Parts > Transformer Tap Changer

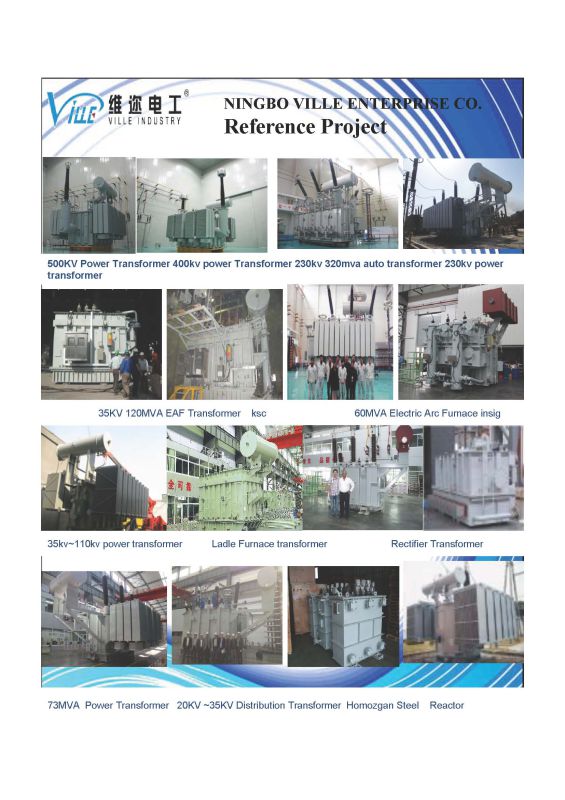

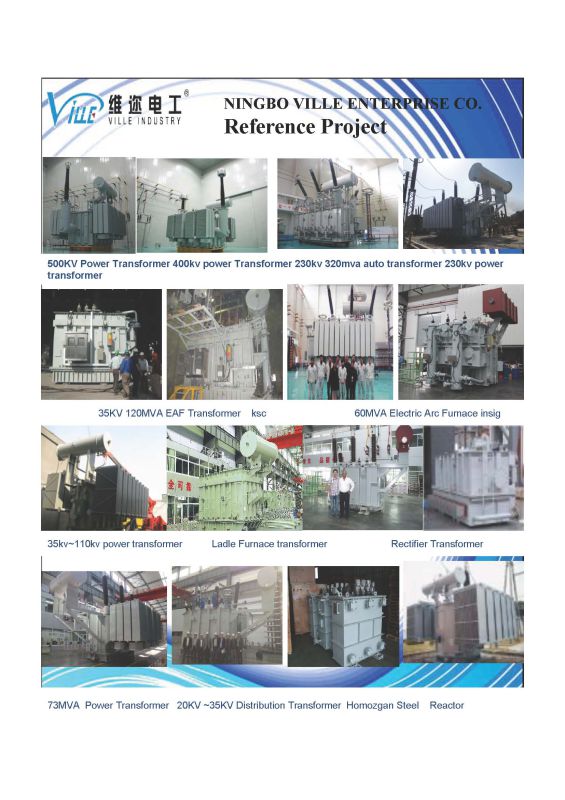

Premium Related Products

Other Products

Hot Products

Centrifugal Ventilation Fan with Good QualityGood Price for Vacuum Circuit Breaker of High Quality and Low VoltagePower SaverRectifier Transformer /Oil Immersed Power TransformerPassive Power Filter (Low Voltage)DC Power Distribution Board of Transformer SubstationThree Phase Resin Insulation Dry Type Power TransformerDistribution Transformer /Power Transformer/Power SubstationCable Distribution Box for Outdoor High VoltageAuto Transformer 330kv-500kv Power Transformer Furnace Transformer220kv Combination Power TransformerElectric Arc Furnace Transformer /Power Supply Transformer Power Distribution TransmissionPackaged Box Type Power Transmission SubstationHigh Voltage Vacuum Circuit Breaker for IndoorMetal Clad Switchgear of Medium / High VoltageMetal Clad Switchgear of High Voltage